The company’s history

In the years 1920-1930 my great-grandfather left the country to work in Westphalia in Germany as a miner. He invested his money in the purchase of land. This is the first 6 ha of land on which today farm buildings are located. Crops are cereals and beets.

After World War II, my grandparents enlarged it to 18 ha and changed their profile to seed crops associated with breeding cattle. This guaranteed profits and development.

However, when in December 1981 President Regan, in response to the imposition of martial law, applied economic sanctions depriving Poland of the most-favored-nation status in trade with the USA, which blocked loans. The lack of export of seed grass led to a fall in prices in the country and forced a change in the production profile. Medicinal herbs have proved to be a promising direction.

In 1982, all fields were sown with chamomile and milk thistle contracted to Herbapol in Poznań. Every year, the assortment was expanded by including other herbs.

Radical changes occur due to the third generation, i.e. my parents. In 1986, they set up a company called “Herbal Production and Processing Plant” They also received a permission from the authorities to employ 10 persons. They obtain permits for the production of medicines and these were the beginnings of the later Vitax company, which in 1993 employed several hundred people. The agricultural department specialized in herb cultivation took the name “Gospodarstwo Zielarskie Mielcarz”.

It is hard to overestimate the contribution of each generation to the company’s development because in Stalinist times until 1956, when the kulaks (the contemptuous name of owners of larger farms) were discriminated, the development was not possible. At that time a socialist future was being built and we all know how it ended.

In 2019, the history of the fourth generation of Mielcarz’s family begins. My wife, Kasia, and I set up the company “Mielcarz Vegetable Drying Plant”. We are the company that continues the 40-year tradition of Mielcarz Herb Holding.

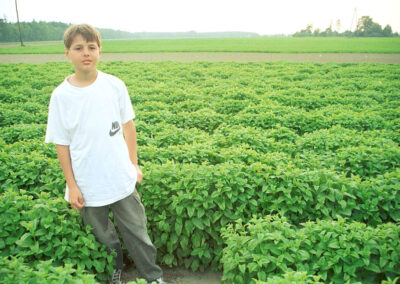

The most important plants are mint, lemon balm, chamomile, St. John’s wort, artichoke which are grown annually on an area of about 150 ha in the standards of the main recipient, Mabagrown: without the use of fungicides and with a minimal amount of pesticides, crops are harvested without contact with the ground, and they are thermally dried. These are high quality pharmaceutical raw materials sold on the German market.

The farm has developed technologies for industrial cultivation and harvesting of herbs. It’s been nominated for the title of the Greater Poland’s Farmer of the Year and Agro Entrepreneur of the Year.

The second specialization of the company is the cultivation of parsley. Every year, 60 to100 ha of it. We guarantee high quality dried products regardless of the weather conditions. Specialized machines, professional employees and all plantations with sprinklers guarantee this.

Mielcarz Vegetable Drying Plant deals only with drying and preparing for sale parsley to do it best.

We have 4 industrial belt dryers that allow to dry 70 tons of raw material per day.

The modern technology allows us to receive a standardized product after 3 hours of drying.

We obtain the raw material from our own plantations and purchased from certified suppliers who are obliged to apply the regulation of plant protection products in accordance not only with EU standards but also with the specifications of our customers. Despite the lack of European standards, we guarantee our customers a level of pyrrolizidine alkaloids (PA) below 400 µg / kg.

Before shipping, we examine each batch in a certified laboratory for pesticide residue and microbiology. At the client’s request, parsley can be sterilized. We apply the principles of Good Manufacturing Practice and HACCP. The raw material is sifted from the remains of sand and insects before the drying.

Magnetic blocks used on production lines as well as metal and non-metal detectors guarantee high product purity. 15 MW of thermal power allows to obtain a temperature of 135 degrees and initial, short-term sterilization of the raw material.

The use of pneumatic tunnels and Allagier screening machines make the raw material free of mineral impurities. Goods are prepared according to customer requirements, these are usually 0.5-2.0 mm fractions and 2.0-4.0 mm. The packaging used are bags with a foil insert. One bag weights about 10 kg.